Power Industry

Pressure density sensors are used for real-time monitoring of SF6 gas pressure and density in power equipment, playing a critical role in the safe operation of power systems. They enable online equipment condition monitoring, leakage early warning, and intelligent operation & maintenance (O&M), contributing to equipment safety, environmental protection, and ensuring the stability and reliability of power systems.

Taking GIS Equipment SF6 Monitoring as an Example:

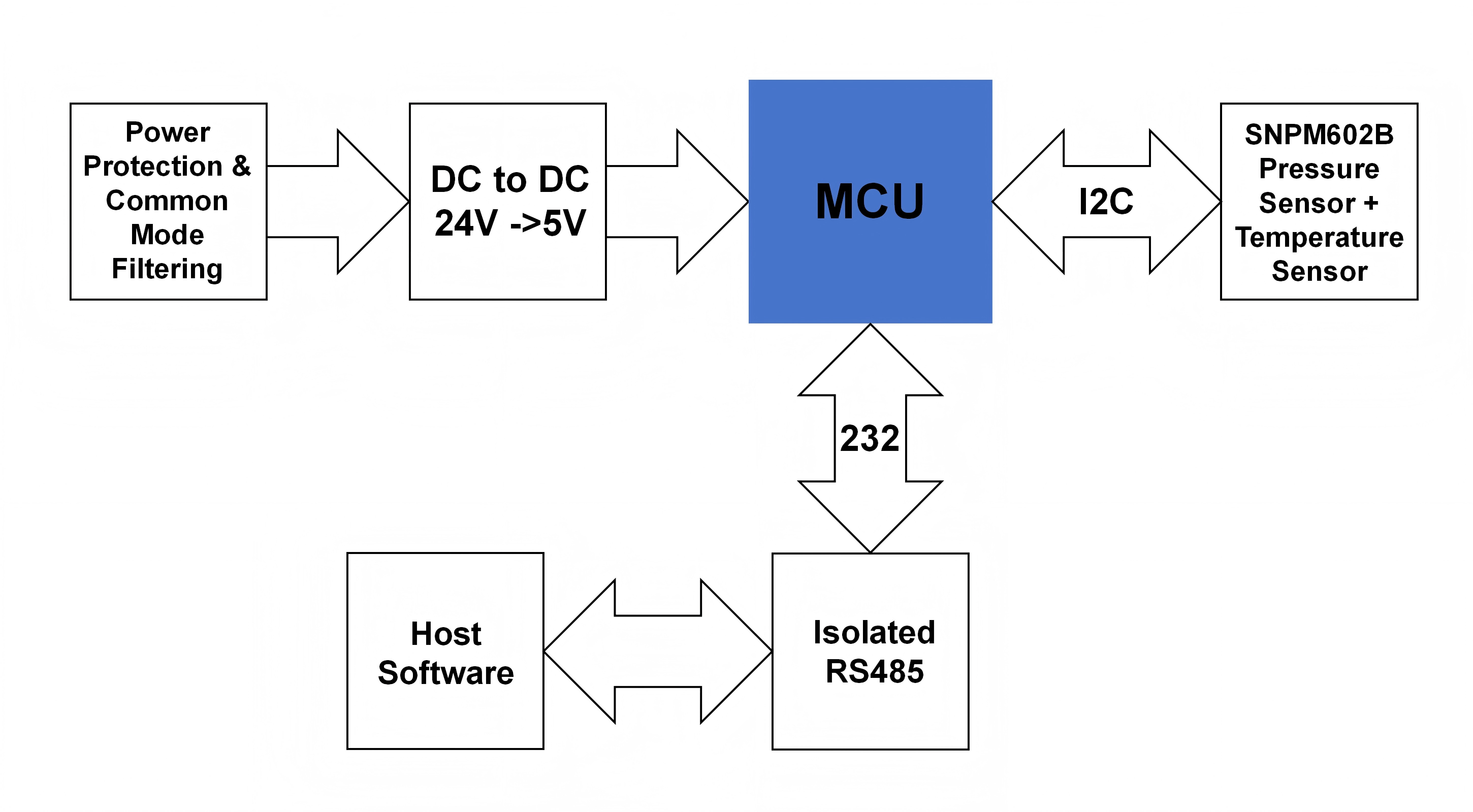

The monitoring system functions to ensure that the SF6 gas density within the GIS equipment remains within the safe range at all times. Its main components include pressure sensors, temperature sensors, density calculation modules, etc. The pressure sensor (such as the SNPM602B high-precision MEMS sensor) measures the real-time pressure of SF6 gas in the gas chamber, while the temperature sensor simultaneously acquires ambient temperature. The system accurately calculates gas density through a multi-stage compensation algorithm. Digital remote density relays or transmitters upload data to the monitoring platform in real-time. Once the density falls below the alarm threshold, the system immediately issues an alert to guide O&M personnel for timely intervention, preventing equipment failure due to degraded insulation performance.